Add to Cart

| RIFI EMT Tube Bend Conduit Bender Aluminum Raw Material 1/2''-1'' | |

| CAT# | SIZE |

| EBM050 | 1/2'' |

| EBM075 | 3/4'' |

| EBM100 | 1'' |

An EMT (Electrical Metallic Tubing) conduit bender is a tool used by electricians and contractors to bend EMT conduits, which are a type of thin-walled metal conduit commonly used to protect and route electrical wiring in buildings. EMT conduits are made of galvanized steel or aluminum and are popular for their lightweight and cost-effective nature.

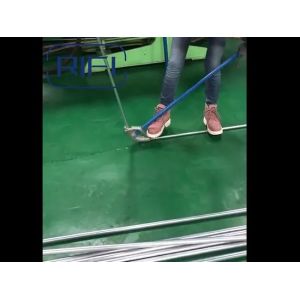

EMT conduit benders come in various sizes to accommodate different diameters of EMT conduits. The bender typically consists of a long handle, a hook or shoe that holds the conduit, and a degree scale to indicate the angle of the bend. Here's how the process generally works:

Preparation: Measure the length of the conduit and mark the point where you want to start the bend.

Setup: Place the conduit into the hook or shoe of the bender, aligning the starting mark with the appropriate reference point on the bender.

Bending: Apply force to the handle of the bender, gradually bending the conduit to the desired angle. The degree scale on the bender helps you achieve precise angles, which is important for maintaining proper electrical conduit installations.

Checking Angle: Use a protractor or angle measurement tool to verify the angle of the bend matches the desired specification.